ASSEMBLY

(First Series)

21. Clean all parts of the Hydrovac thoroughly. Bendix Cleaner is recommended

for cleaning metal parts. Use alcohol for cleaning hydraulic parts. Do not use

gasoline, kerosene or Bendix Cleaner on rubber parts or on parts from the hydraulic

system.

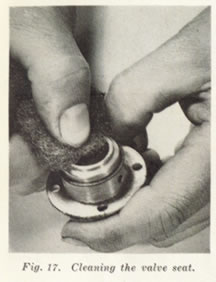

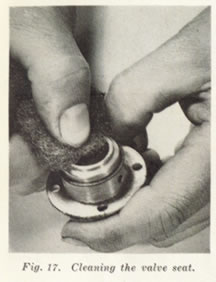

22. Inspect all parts for wear or damage. if the valve seats are slightly pitted

or corroded, they may be cleaned with fine steel wool, Fig. 17.

23. Install a new diaphragm and new gaskets in the control valve. Clean all

flange surfaces to insure an air tight fit. Compress the diaphragm spring and

washer as shown in Fig. 18 to assemble link pins in the valve stems.

Fig. 19 shows where the special washer will be on the pins in the lower

body section when the diaphragm is in place.

24. Lubricate the internal linkage of the control valve with Bendix Cable Lubricant.

25. When assembling the control valve, be sure the by pass holes in the spacer

plate, valve body, diaphragm and gasket all line up so that the passage is clear.

See illustration Fig. 12.

26. While tightening the diaphragm screws, Fig. 20, hold the diaphragm down

just enough to close the vacuum valve. This prevents buckling of the diaphragm

between the screw holes.

27. If the hydraulic cylinder of the control valve is scored or pitted, the

part should be replaced. It is not practicable to refinish this bore because

of its small diameter and the unavoidable enlargement of the bore.

28. When assembling the control valve hydraulic cylinder and plunger. be particularly

sure that all parts are clean and free from grit. Blow out all passages with

compressed air and wipe the bore of the cylinder clean and dry with a cloth.

Do not lay parts on the bare work bench where they may pick up dirt; place them

on a clean paper.